Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Metal materials in stamping parts also have material quality inspections, such as material hardness, mold hardness, etc. How are they inspected? Today, we will share relevant contents with you.

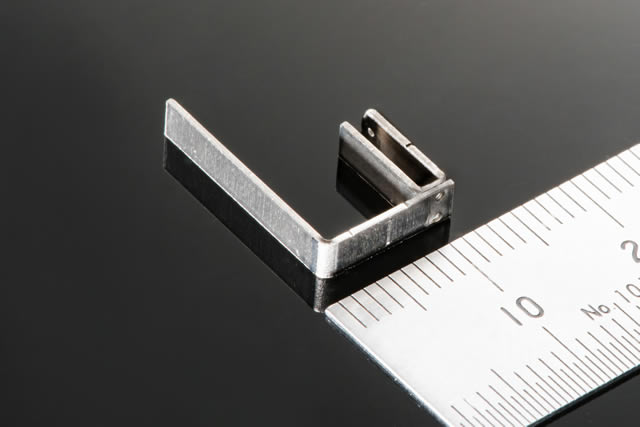

First of all, we understand that there are two kinds of testing for precision metal stamping parts: stamping materials and stamping dies. Different products have different testing methods.

Rockwell hardness tester is generally used for precision metal stamping parts. It is more suitable for small stamping parts with complicated shapes. It is impossible to detect the plane on the ordinary table Rockwell hardness tester.

PHP series of portable surface Rockwell hardness tester: more suitable for testing the hardness of these stamping parts. Alloy stamping parts are metal processing, is commonly used in the field of mechanical manufacturing. Stamping parts processing is a processing method that uses molds to separate or form metal plates and strips. It has a wide range of applications.

1、Hardness testing of precision metal stamping materials

Verification of material hardness of stamping parts: the purpose is to determine whether the annealing level of purchased metal sheets is suitable for subsequent stamping parts processing. Different types of stamping parts need plates with different hardness levels.

For aluminum alloy plates processed as stamping parts, pure aluminum plates with a material thickness of more than 13mm or low hardness aluminum alloy plates can use a Babbitt hardness tester.

2、Hardness testing of precision metal stamping dies

The important material of stamping die is die steel (including tool steel and high-speed steel), sometimes cemented carbide is used.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox